Low frequency induction heaters

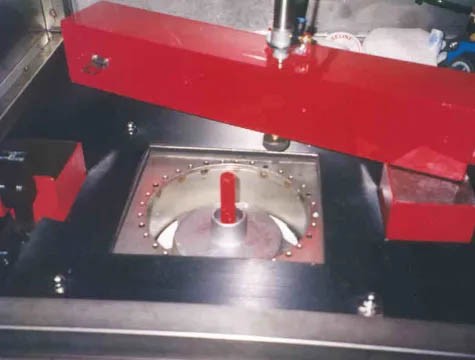

Schaeffler Smart Maintenance Tools designs and builds customized induction heaters for serial heating of parts, such as bearings, sprockets, gears, bushings, rings and aluminium housings of E-motors. If fast heating and accurate temperatures are important, these Low frequency "Specials" offer solid solutions.

- Spectacular heating times: 15 to 300 seconds

- Temperatures up to 480°C

- Suitable for the most popular metals and alloys.

- Automatic, semi-automatic or manually operated.

- For serial heating or heating of non-standard shapes

Mid frequency induction heaters

Mounting and dismounting solutions with Mid frequency heaters.

By applying medium-frequency technology, effective energy transfer takes place to the workpiece, which makes it heat up quickly and easily. The MF Quick-Heater consists of a generator with a fixed or flexible inductor. Inductors are custom made to fit special applications. Thanks to the double temperature measurement (Delta-T) perfect controlled heating is possible, fast or slow, depending on the application.

Why induction heating?

Induction heating is a superior, fast and controlled heating method. It is a safe, energy-saving and environmentally friendly alternative to traditional heating methods such as ovens, oil baths or gas burners. These are a risk for personal safety and a healthy working environment as well as causing odor and smoke nuisance.

It is common knowledge that a correct mounting method extends the bearing life. Controlled stress-free heating prevents unnecessary damage, while retaining the original bearing lubrication. Ideal for sealed bearings (2RS-ZZ). Bearing manufacturers recommend controlled induction heating as the best practice for bearing mounting.